Certified Aluminum Bus Welding for Substations and Switchyards

Precision Welds, Fast Response Times, and Code-Compliant Repairs... That's Basically Everything You Wanted, Right?

A Reliable Welding Partner for High-Stakes Substation Work

When you're working on a substation or switchyard, every weld needs to be right the first time. So make the right call the first time. West Mountain Welding delivers certified aluminum bus welding backed by field experience, fast mobilization, and an understanding of what's at stake. Whether you're building new, expanding capacity, or handling an emergency repair, we've got you like the hairs on your back.

Serving Contractors, utilities, and EPC firms across the beautiful State of Utah, WMW is the choice even your mother-in-law can make when you need precision aluminum welding without delays or do-overs.

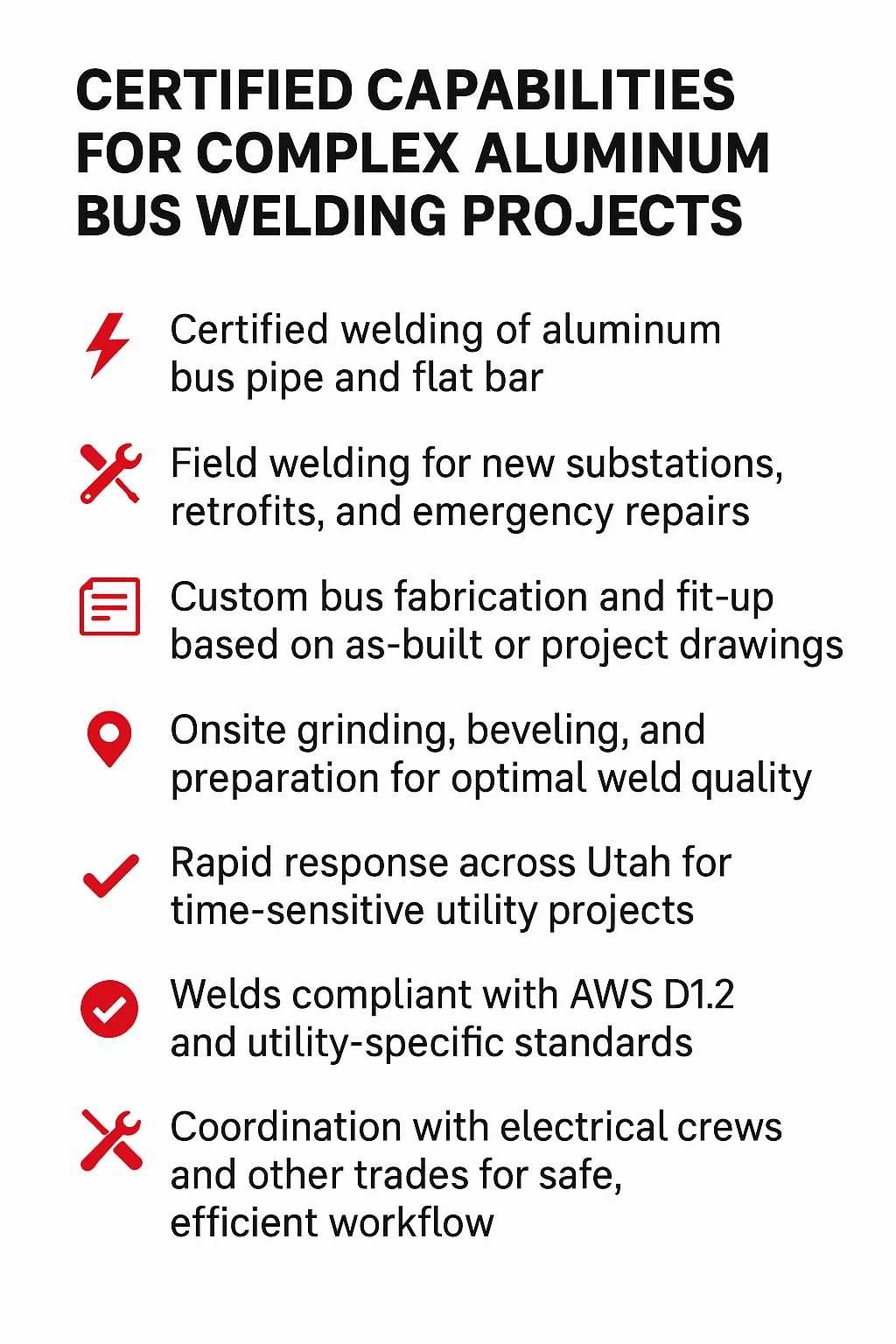

Certified Capabilities for Complex Aluminum Bus Welding Projects

Substation work demands more than just welding skill, it takes precision, preparation, the ability to preform under pressure and laser vision (it saves us from carrying around welding equipment). West Mountain Welding brings the right combination of field-tested experience and certified capabilities to support utility contractors, engineers, and construction managers with demanding aluminum bus welding needs.

Certified welding of aluminum bus pipe and flat bar

Field welding for new substations, retrofits, and emergency repairs

Custom bus fabrication and fit-up based on as-built or project drawings

Onsite grinding, beveling, and preparation for optimal weld quality

Rapid response across Utah for time-sensitive utility projects

Welds compliant with AWS D1.2 and utility-specific standards

Coordination with electrical crews and other trades for safe, efficient workflow

FAQS

1. What standards do your aluminum bus welds meet?

All aluminum bus welding is performed to meet AWS D1.2 structural welding standards and any utility-specific requirements outlined in your project specs.

2. Can you perform emergency or short-notice welds on live substations?

Yes. We specialize in emergency field welding and rapid mobilization. We coordinate closely with your teams to work safely around energized equipment or during planned outages.

3. What types of aluminum bus do you weld?

We weld both tubular and flat bar aluminum bus, including bolted or welded transitions, terminations, and complex joint configurations.

4. Do you work directly with utilities or just with subcontractors?

We partner with general contractors, electrical contractors, EPC firms, and utilities directly. Whether you’re leading the job or managing a substation project, we can integrate seamlessly.

5. What regions do you service?

We serve substation projects across Utah and can travel to job sites in surrounding Mountain West states as needed. If you’re on a tight schedule or remote site, we’re equipped to come to you.